A computerized maintenance management system (CMMS) is a type of management software that performs functions in support of management and tracking of Operation and Maintenance (O&M) activities.

CMMS Needs Assessment In determining the need for a CMMS, facility managers should assess their current mode of operation. Key questions to ask include:

• Do you have an effective way to generate and track work orders? How do you verify the work was done efficiently and correctly? What is the notification function upon completion?

• Are you able to access historical information on the last time a system was serviced, by whom, and for what condition?

• How are your spare-parts inventories managed and controlled? Do you have either excess inventories or are you constantly waiting for parts to arrive?

• Do you have an organized system to store documents (electronically) related to O&M procedures, equipment manuals, and warranty information?

• When service staff are in the field what assurances do you have that they are compliant with all life, health and safety issues (e.g., lock and tag) and are using the right tools/equipment for the task?

• How are your assets, i.e., equipment and systems, tracked for reporting and planning?

If the answers to these questions are not well defined or lacking – you may consider investigating, the benefits a well implemented CMMS may offer.

CMMS Capabilities

CMMS systems automate most of the logistical functions performed by maintenance staff and management. CMMS systems come with many options and have many advantages over manual maintenance tracking systems. Depending on the complexity of the system chosen, typical CMMS functions may include the following:

• Work order generation, prioritization, and tracking by equipment/component.

• Historical tracking of all work orders generated which become sortable by equipment, date, person responding, etc.

• Tracking of scheduled and unscheduled maintenance activities.

• Storing of maintenance procedures as well as all warranty information by component.

• Storing of all technical documentation or procedures by component.

• Real-time reports of ongoing work activity.

• Calendar- or run-time-based preventive maintenance work order generation.

• Capital and labor cost tracking by component as well as shortest, median, and longest times to close a work order by component.

• Complete parts and materials inventory control with automated reorder capability.

• PDA interface to streamline input and work order generation.

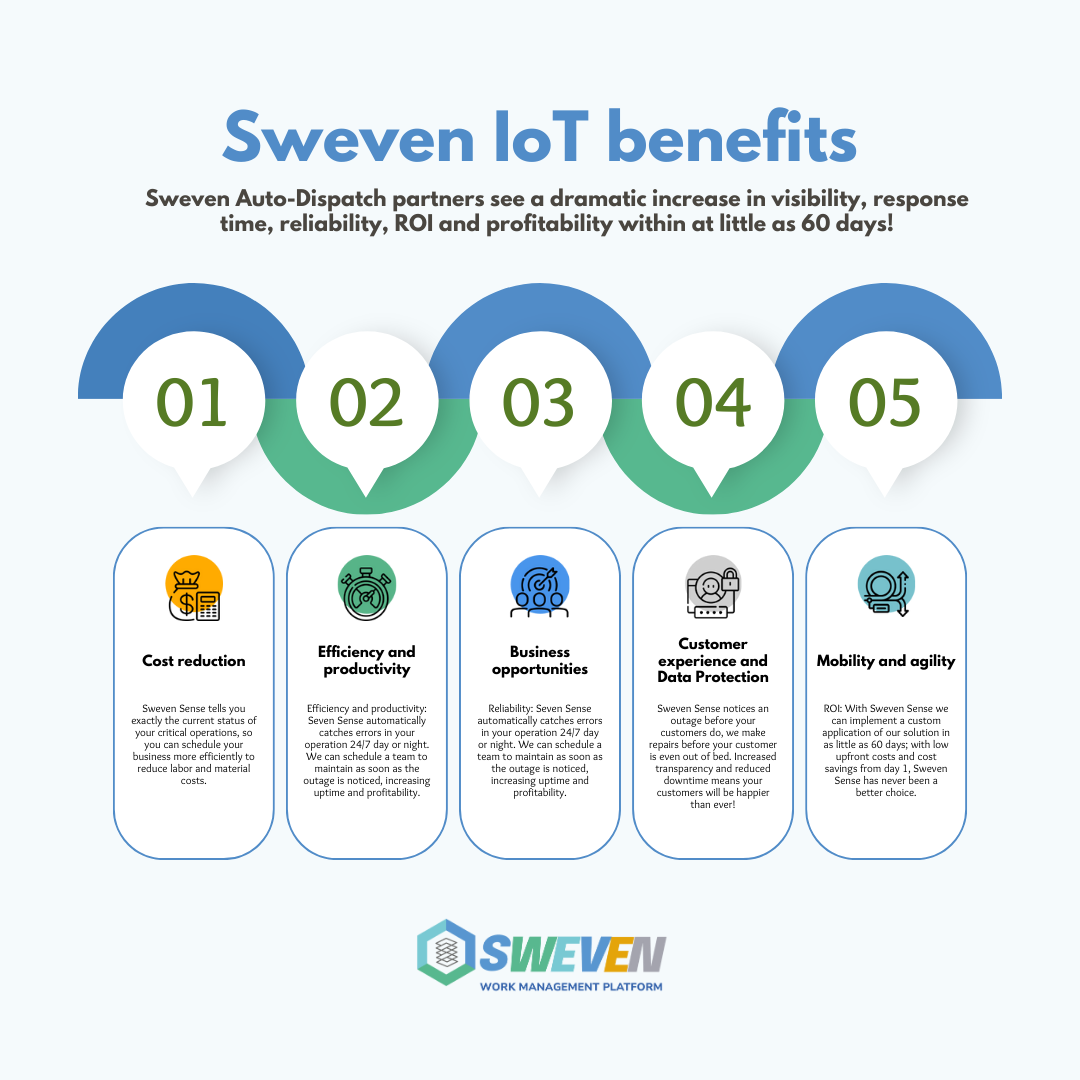

• Outside service call/dispatch capabilities.

Source:

Operation & Maintenance Best Practices, Release 3.0. Chapter 4

A Guide to Achieving Operational Efficiency

U.S Department of Energy. Energy Efficiency & Renewable Energy