Aging infrastructure and outdated equipment present significant challenges for facility managers across various industries. As buildings and systems grow older, the frequency and complexity of maintenance tasks increase, often leading to higher costs, unexpected downtime, and operational inefficiencies. To address these issues effectively, it’s essential to implement a proactive maintenance schedule and invest in modernization and replacement strategies. Here’s how facility managers can tackle the maintenance of aging infrastructure to ensure optimal performance and longevity.

Understanding the Pain Point: Managing Maintenance for Aging Infrastructure

Aging infrastructure refers to buildings, systems, and equipment that have exceeded their expected lifespan but are still in use. Common issues associated with aging infrastructure include:

- Increased Maintenance Needs: Older systems require more frequent repairs and maintenance, which can strain resources.

- Higher Costs: Maintenance and repair costs for aging equipment can be significantly higher compared to newer, more efficient alternatives.

- Operational Downtime: Unexpected failures and breakdowns can lead to costly downtime, disrupting operations and affecting productivity.

Safety Concerns: Outdated equipment and systems can pose safety risks to employees and occupants.

Solution 1: Implementing a Proactive Maintenance Schedule

One of the most effective strategies for managing aging infrastructure is to adopt a proactive maintenance approach. Proactive maintenance involves regular, scheduled inspections and maintenance tasks designed to prevent issues before they arise. This approach can significantly reduce the likelihood of unexpected failures and extend the lifespan of existing equipment.

Key components of a proactive maintenance schedule include:

- Regular Inspections: Conduct routine inspections of all critical systems and equipment to identify potential issues early.

- Preventive Maintenance: Schedule regular maintenance tasks based on manufacturer recommendations and industry best practices. This can include lubrication, calibration, cleaning, and component replacement.

- Condition Monitoring: Utilize advanced monitoring technologies to track the condition of equipment in real-time. This can include vibration analysis, thermal imaging, and other diagnostic tools.

- Maintenance Management Software: Implement a computerized maintenance management system (CMMS) to streamline scheduling, track maintenance tasks, and manage work orders efficiently.

Solution 2: Investing in Modernization and Replacement Strategies

While proactive maintenance can help manage aging infrastructure, there comes a point when modernization or replacement becomes necessary. Investing in modern equipment and systems can improve efficiency, reduce maintenance costs, and enhance overall operational performance.

Modernization and replacement strategies should consider the following:

- Cost-Benefit Analysis: Evaluate the costs of ongoing maintenance and repairs against the benefits of investing in new equipment. Consider factors such as energy efficiency, operational reliability, and potential downtime reduction.

- Prioritization: Identify and prioritize critical systems and equipment that have the most significant impact on operations. Focus on modernizing or replacing these first to achieve the greatest benefits.

- Energy Efficiency: Opt for modern equipment that offers improved energy efficiency. This can lead to substantial cost savings over time and support sustainability goals.

- Scalability and Flexibility: Choose solutions that offer scalability and flexibility to accommodate future growth and technological advancements.

- Funding and Financing: Explore various funding and financing options, such as grants, loans, and leasing arrangements, to support modernization and replacement projects.

The Role of Technology in Managing Aging Infrastructure

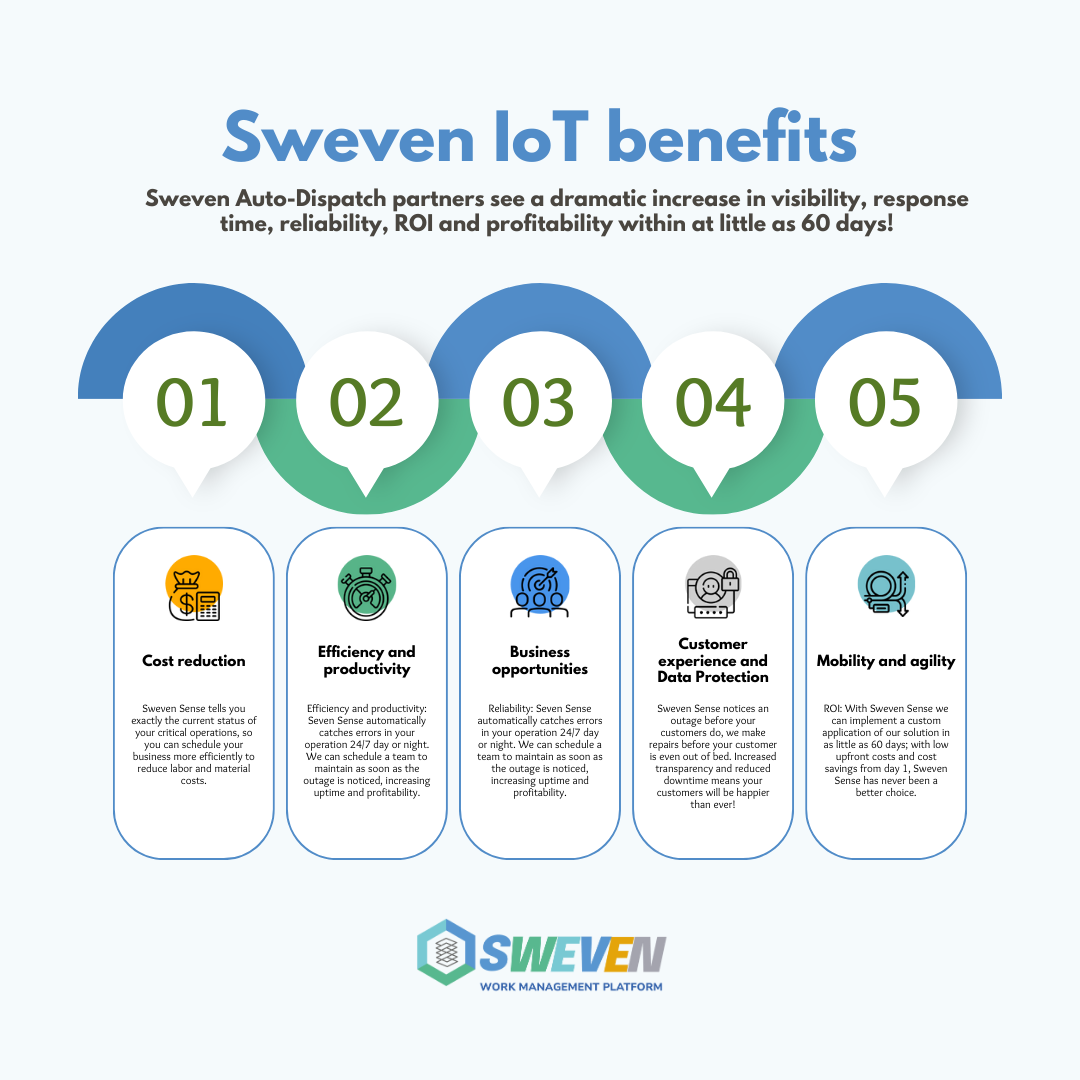

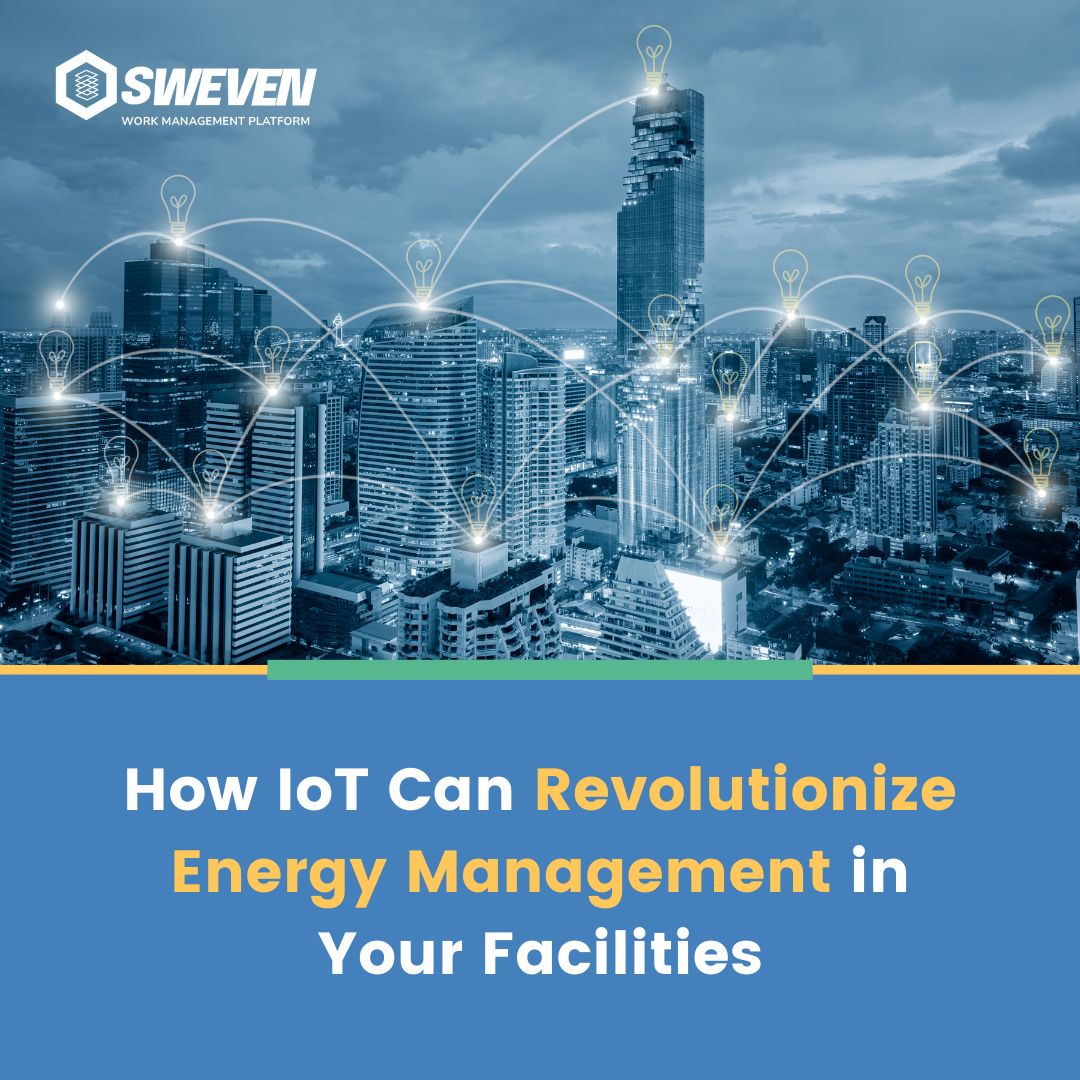

Advancements in technology play a crucial role in managing aging infrastructure more effectively. The integration of smart technologies and the Internet of Things (IoT) allows facility managers to gain deeper insights into the condition and performance of their assets.

- IoT Sensors: Deploy IoT sensors to monitor critical parameters such as temperature, humidity, pressure, and vibration in real-time. This data can help predict failures and optimize maintenance schedules.

- Building Management Systems (BMS): Utilize BMS to centralize control and monitoring of various building systems, including HVAC, lighting, and security. This enhances efficiency and allows for more precise management of resources.

Data Analytics: Leverage data analytics to identify trends, patterns, and anomalies in equipment performance. This can inform decision-making and support the development of more effective maintenance strategies.

Conclusion

Managing maintenance for aging infrastructure and outdated equipment is a complex but essential task for facility managers. By implementing a proactive maintenance schedule and investing in modernization and replacement strategies, organizations can address the challenges posed by aging infrastructure effectively. These approaches not only reduce maintenance costs and operational downtime but also enhance safety, efficiency, and overall performance.

In an era where technology continues to evolve rapidly, staying ahead of maintenance issues and investing in modern solutions is crucial. By adopting these strategies, facility managers can ensure that their infrastructure remains reliable, efficient, and capable of supporting the organization’s long-term goals.