Reactive maintenance—addressing equipment failures only after they occur—can lead to costly downtime, expensive emergency repairs, and disruptions to operations. Preventive maintenance (PM) provides a proactive approach, focusing on routine inspections and servicing to avoid equipment breakdowns. Implementing a comprehensive PM plan requires strategic steps that align with your facility’s needs. Here’s a detailed guide to help you make the shift effectively.

Step 1: Assess and Prioritize Your Assets

Action

Begin by taking inventory of all critical assets and systems in your facility, such as HVAC units, electrical systems, plumbing, elevators, and lighting. Evaluate each asset based on:

- Criticality to Operations: How essential is the asset to day-to-day functionality?

- Condition: What is the current state of the equipment?

- Age and Usage: How old is the asset, and how frequently is it used?

- Maintenance History: Has the equipment experienced frequent issues or repairs?

Once assessed, categorize and prioritize these assets. High-priority assets should receive more frequent and detailed attention.

Why It Matters

This step ensures that resources are directed toward the most critical and vulnerable equipment, minimizing the risk of disruptions and improving overall operational reliability.

Step 2: Develop a Scheduled Maintenance Calendar

Action

Create a detailed maintenance schedule for each asset based on the following:

- Manufacturer Recommendations: Follow the guidelines provided by the equipment manufacturer.

- Historical Data: Consider past performance and issues faced with the asset.

- Operational Demands: Factor in how often the equipment is used and under what conditions.

Plan maintenance tasks such as:

- Routine inspections

- Cleaning and lubrication

- Replacing worn-out parts

- Testing for optimal performance

Use software or tools to automate scheduling, send reminders, and track completed tasks. Organize the calendar to balance workloads, preventing periods of over-commitment or neglect.

Why It Matters

A maintenance calendar keeps all tasks organized and ensures that potential issues are identified and resolved before they escalate, reducing the risk of equipment failure and unplanned downtime.

Step 3: Train Your Team and Track Performance

Action

Educate your maintenance team about the importance of preventive maintenance and how it differs from reactive approaches. Provide specific training on tasks outlined in the maintenance schedule, including troubleshooting techniques and safety protocols.

Implement performance tracking to measure the effectiveness of your PM plan. Key metrics to monitor include:

- Reduction in emergency repairs

- Decrease in equipment downtime

- Compliance with scheduled tasks

- Cost savings from fewer major repairs

Use regular reviews to identify areas for improvement and adjust the plan accordingly.

Why It Matters

A well-trained team ensures consistency and adherence to the PM plan, while performance tracking helps measure success, demonstrate ROI, and refine the process for even better results.

Why Choose Sweven BPM for Your Preventive Maintenance Plan?

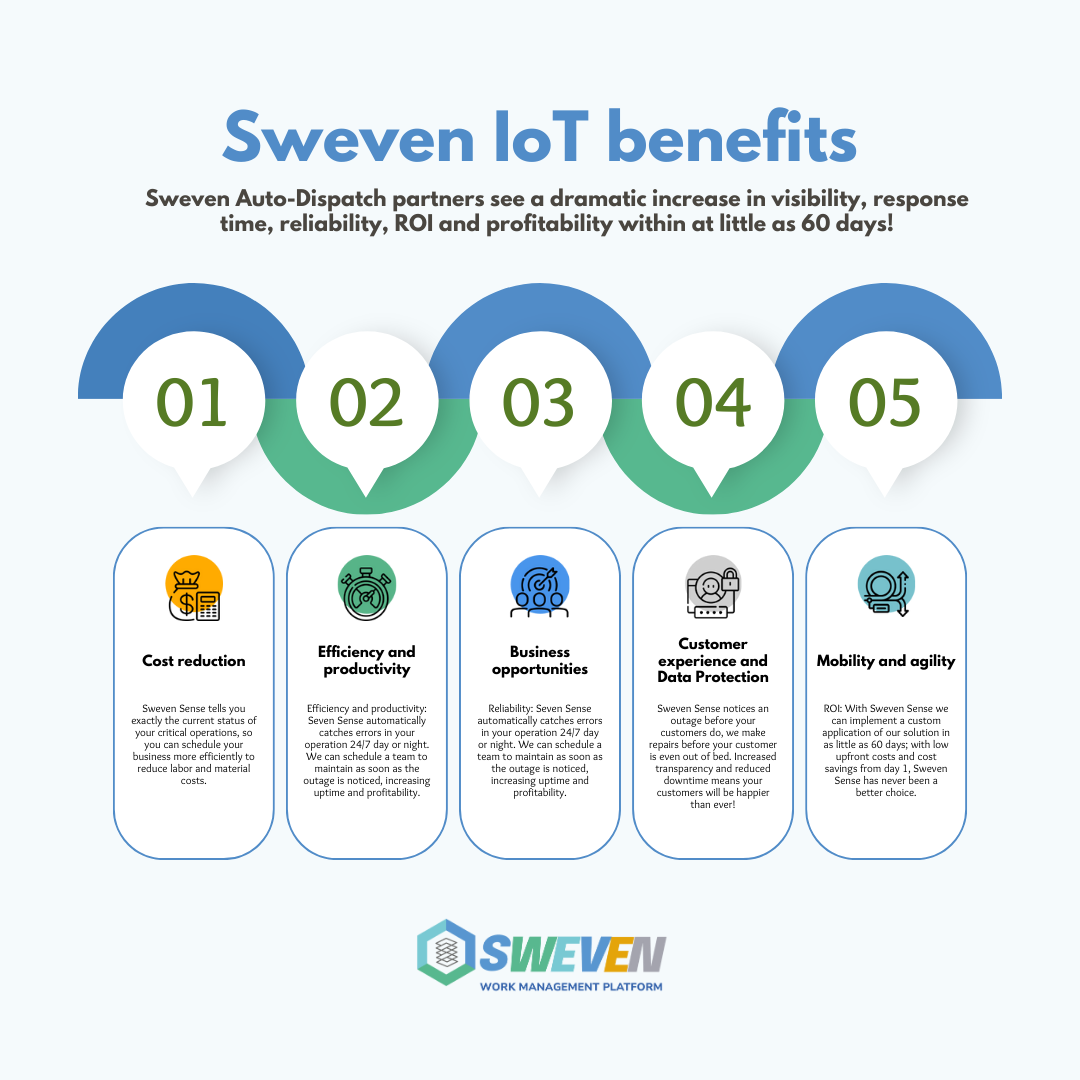

Implementing a successful PM plan can be challenging without the right tools to streamline asset management, automate scheduling, and monitor progress. Sweven BPM offers an all-in-one solution to support every aspect of your preventive maintenance strategy:

Comprehensive Asset Management

Sweven BPM’s asset management module allows you to document all equipment, track maintenance histories, and prioritize assets based on criticality and condition.

Automated Maintenance Scheduling

Say goodbye to missed maintenance tasks. Sweven BPM enables you to create customized schedules for inspections, repairs, and replacements. The system sends automated reminders, ensuring timely execution and reducing the risk of oversight.

Real-Time Performance Tracking

Sweven BPM provides advanced analytics to track key performance indicators like downtime reduction, task completion rates, and cost savings. This data empowers you to refine your plan continually.

Team Collaboration and Training Tools

Sweven BPM offers a centralized platform for team communication, task assignments, and access to training resources. This ensures consistency and knowledge sharing across your maintenance team.

Scalable and User-Friendly

Whether you manage a single building or multiple facilities, Sweven BPM is scalable to fit your needs. Its intuitive interface makes it easy for teams to adopt and use effectively.

Conclusion

Shifting from reactive to proactive maintenance requires strategic planning, ongoing team collaboration, and reliable tools. By following this step-by-step guide, you can develop a preventive maintenance plan that enhances efficiency, reduces costs, and ensures operational stability.

With Sweven BPM, you have a partner to simplify and elevate your maintenance efforts. From asset prioritization to performance tracking, Sweven BPM ensures every step of your PM plan is optimized for success.

Ready to transform your maintenance strategy? Contact Sweven BPM today and see how it can help you achieve proactive excellence.