Traditional maintenance models rely on reactive or scheduled maintenance—waiting for something to break or following routine check-ups, which often means wasted resources or missed issues.

This is where IoT sensors come into play and completely transform the way we approach maintenance.

How IoT Enhances Preventive Maintenance:

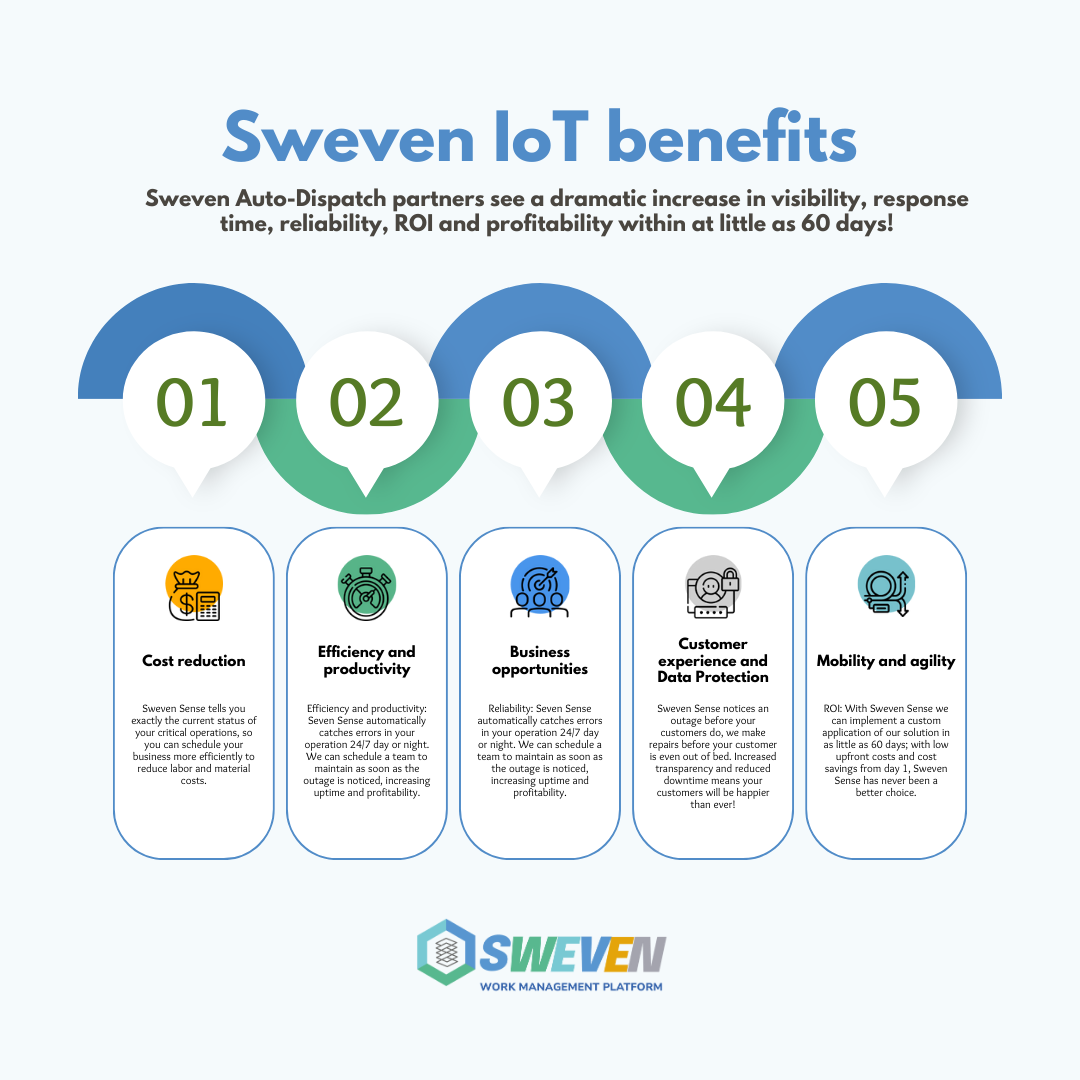

-Real-Time Monitoring: IoT sensors provide 24/7 real-time data on equipment performance, environmental conditions, and other critical parameters. Instead of waiting for a problem to arise, these sensors alert facilities teams when something is operating outside of the norm—allowing for immediate action to prevent breakdowns.

-Predictive Insights: By continuously collecting and analyzing data, IoT sensors can predict when equipment is likely to fail. Facilities professionals can use this data to perform maintenance at just the right time—before small issues escalate into costly repairs. This shift from reactive to predictive maintenance extends the life of equipment and significantly reduces downtime.

-Targeted Maintenance: Traditional preventive maintenance often leads to unnecessary work or replacing parts that still have plenty of life left. IoT sensors, however, allow for condition-based maintenance, where you only service equipment that actually needs attention. This leads to more efficient use of resources and reduced operational costs.

-Remote Diagnostics: IoT sensors make it possible to diagnose problems remotely. Before sending a technician out, you can have real-time data that helps identify the issue in advance. This saves time, optimizes workflows, and ensures the right person is dispatched with the correct tools.

Why This Matters:

-Lower Costs: By addressing issues before they become bigger problems, facilities managers can significantly reduce repair and labor costs.

-Increased Equipment Lifespan: Regular monitoring and targeted interventions lead to better care of your equipment, extending its lifespan.

-Minimal Disruptions: Predictive maintenance ensures that equipment is serviced during non-critical times, reducing disruption to building operations.

The future of facilities management is proactive, not reactive. How are you leveraging IoT in your preventive maintenance strategy?