Introduction

The Internet of Things (IoT) and smart devices have revolutionized how businesses operate, offering unprecedented levels of connectivity and data collection. However, many organizations struggle with efficiently utilizing these technologies, often missing out on their full potential. This blog explores the challenges of inefficient use of IoT and smart devices and presents advanced analytics and artificial intelligence (AI) for predictive maintenance as a powerful solution.

The Problem: Inefficient Use of IoT and Smart Devices

Despite the widespread adoption of IoT and smart devices, many businesses face challenges in harnessing their capabilities effectively:

1. Data Overload: IoT devices generate massive amounts of data, which can be overwhelming to process and analyze without the right tools.

2. Lack of Integration: Many IoT systems operate in silos, making it difficult to integrate data across different devices and platforms for comprehensive insights.

3. Reactive Maintenance: Businesses often rely on reactive maintenance strategies, addressing issues only after they occur, leading to unplanned downtime and higher costs.

4. Insufficient Analytical Capabilities: Without advanced analytics, businesses struggle to derive actionable insights from IoT data, limiting their ability to optimize operations and predict failures.

5. High Operational Costs: Inefficient use of IoT devices can result in higher operational costs due to frequent breakdowns, energy inefficiencies, and manual intervention.

The Solution: Leveraging Advanced Analytics and AI for Predictive Maintenance

Advanced analytics and AI offer powerful tools to overcome these challenges by enabling predictive maintenance, which anticipates and addresses equipment issues before they occur. Here’s how these technologies can transform the use of IoT and smart devices:

Predictive Maintenance with Advanced Analytics

1. Data Aggregation and Integration: Advanced analytics platforms can aggregate and integrate data from various IoT devices, breaking down silos and providing a unified view of operations.

2. Real-Time Monitoring: Analytics tools enable real-time monitoring of equipment performance, allowing businesses to detect anomalies and potential issues as they arise.

3. Trend Analysis: By analyzing historical data, advanced analytics can identify patterns and trends that indicate the likelihood of future failures or maintenance needs.

4. Root Cause Analysis: When issues occur, advanced analytics can help identify the root causes, providing insights into how similar problems can be prevented in the future.

AI-Driven Predictive Maintenance

1. Machine Learning Algorithms: AI, particularly machine learning (ML) algorithms, can analyze vast amounts of IoT data to predict when equipment is likely to fail. These algorithms learn from historical data and improve over time, increasing their predictive accuracy.

2. Predictive Modeling: AI can create predictive models that forecast maintenance needs based on data patterns, usage conditions, and environmental factors. These models help in planning maintenance activities proactively.

3. Anomaly Detection: AI can detect deviations from normal operating conditions that may indicate potential issues. Early detection allows for timely intervention, minimizing downtime and preventing costly repairs.

4. Optimization of Maintenance Schedules: AI can optimize maintenance schedules by predicting the best times for maintenance activities, balancing operational efficiency with minimal disruption.

Implementing Predictive Maintenance with Advanced Analytics and AI

To successfully implement predictive maintenance using advanced analytics and AI, businesses need a strategic approach:

1. Assessment and Planning: Evaluate your current IoT infrastructure and identify areas where predictive maintenance can add value. Develop a detailed implementation plan that outlines objectives, timelines, and required resources.

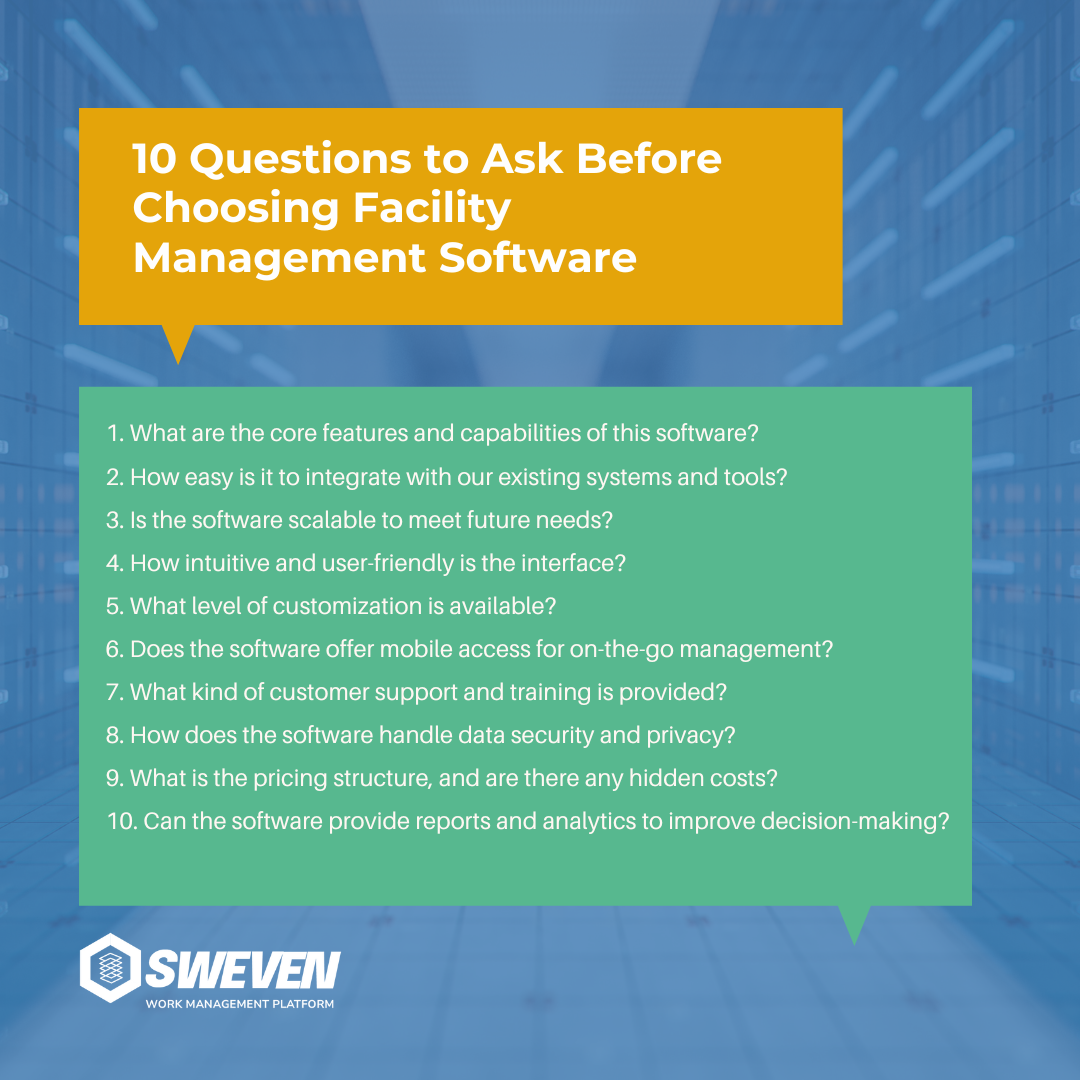

2. Selecting the Right Tools: Choose advanced analytics and AI tools that fit your specific needs. Consider factors such as compatibility with existing systems, scalability, and ease of use.

3. Data Integration: Ensure seamless integration of data from various IoT devices into your analytics platform. This may involve using APIs, data connectors, or middleware solutions.

4. Training and Development: Train your team on using the new tools and interpreting the insights generated. Continuous education ensures effective adoption and utilization.

5. Pilot Testing: Start with a pilot project to test the effectiveness of predictive maintenance in a controlled environment. Use this phase to gather feedback and make necessary adjustments.

6. Full-Scale Deployment: Once the pilot phase is successful, roll out predictive maintenance across all relevant operations. Monitor the performance and adjust as needed to optimize results.

7. Continuous Improvement: Regularly review and analyze the performance of your predictive maintenance system. Use the insights gained to refine algorithms and enhance predictive accuracy.

Benefits of Predictive Maintenance with Advanced Analytics and AI

Implementing predictive maintenance using advanced analytics and AI offers numerous benefits:

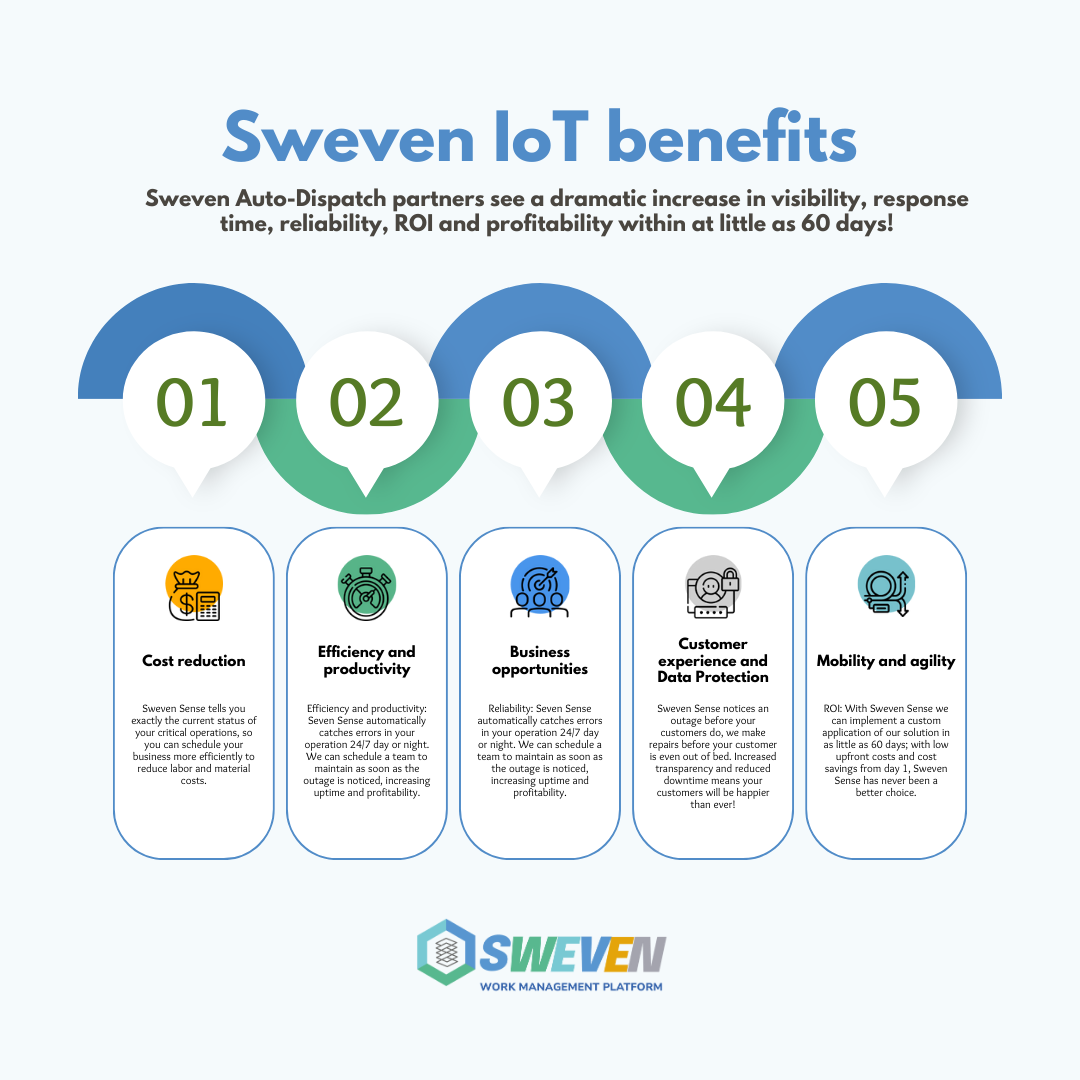

1. Reduced Downtime: Predictive maintenance minimizes unplanned downtime by addressing issues before they escalate into major problems.

2. Cost Savings: By preventing costly repairs and optimizing maintenance schedules, businesses can significantly reduce operational costs.

3. Improved Equipment Lifespan: Regular and timely maintenance extends the lifespan of equipment, enhancing the return on investment.

4. Enhanced Operational Efficiency: Real-time monitoring and predictive insights enable more efficient and reliable operations.

5. Data-Driven Decision Making: Advanced analytics and AI provide actionable insights that support informed decision-making and strategic planning.

Conclusion

The inefficient use of IoT and smart devices can hinder operational efficiency and increase costs. However, leveraging advanced analytics and AI for predictive maintenance offers a powerful solution to these challenges. By adopting these technologies, businesses can unlock the full potential of their IoT infrastructure, ensuring optimal performance, reduced downtime, and significant cost savings.

Call to Action

Are you ready to transform your IoT operations with predictive maintenance? Contact us today to learn more about our advanced analytics and AI solutions. Let us help you harness the power of predictive maintenance to achieve greater efficiency and reliability in your operations.