Introduction

In any organization, effective coordination between maintenance teams is crucial for ensuring smooth operations, timely repairs, and optimal asset performance. However, many businesses struggle with a lack of coordination between maintenance teams, leading to inefficiencies, delays, and increased downtime. This blog explores the challenges posed by the lack of coordination between maintenance teams and presents centralized communication platforms as a solution to facilitate collaboration and streamline maintenance processes.

The Problem: Lack of Coordination Between Maintenance Teams

The lack of coordination between maintenance teams can result in various challenges that impact organizational efficiency and productivity:

1. Duplication of Efforts: Without proper coordination, multiple maintenance teams may unknowingly work on the same issue simultaneously, leading to wasted time and resources.

2. Communication Breakdowns: Ineffective communication channels and fragmented systems hinder the exchange of information between maintenance teams, resulting in misunderstandings and errors.

3. Missed Deadlines: Without clear assignment of tasks and timelines, maintenance activities may be delayed, causing equipment downtime and disruption to operations.

4. Inefficient Resource Allocation: Poor coordination leads to suboptimal allocation of resources, with some teams overburdened while others remain underutilized.

5. Lack of Accountability: Without clear roles and responsibilities, accountability for maintenance tasks may be unclear, leading to finger-pointing and blame-shifting when issues arise.

The Solution: Facilitating Collaboration through Centralized Communication Platforms

Centralized communication platforms offer a solution to the lack of coordination between maintenance teams by providing a unified, real-time communication hub for all stakeholders. These platforms enable teams to collaborate effectively, share information, assign tasks, and track progress seamlessly. Here’s how:

Key Features and Benefits of Centralized Communication Platforms

1. Real-Time Communication

– Instant Messaging: Centralized communication platforms offer instant messaging features that allow maintenance teams to communicate in real-time, facilitating quick decision-making and problem-solving.

– Discussion Forums: Dedicated discussion forums or channels provide a space for teams to share updates, ask questions, and exchange ideas, fostering collaboration and knowledge sharing.

2. Task Management and Assignment

– Task Boards: Task management tools enable teams to create, assign, and track maintenance tasks on centralized boards or dashboards, providing visibility into task status and progress.

– Priority Setting: Teams can prioritize tasks based on urgency and importance, ensuring that critical maintenance activities are addressed promptly.

3. Document and Knowledge Sharing

– Document Repositories: Centralized platforms include document repositories where teams can store and access maintenance manuals, equipment specifications, and standard operating procedures.

– Knowledge Base: A knowledge base feature allows teams to capture and share best practices, troubleshooting guides, and lessons learned, promoting continuous improvement and efficiency.

4. Calendar Integration and Scheduling

– Calendar Integration: Integration with calendar tools enables teams to schedule maintenance activities, meetings, and inspections, ensuring that all stakeholders are aware of upcoming events and deadlines.

– Resource Allocation: Teams can allocate resources, such as equipment, materials, and personnel, based on scheduled maintenance activities and availability.

5. Reporting and Analytics

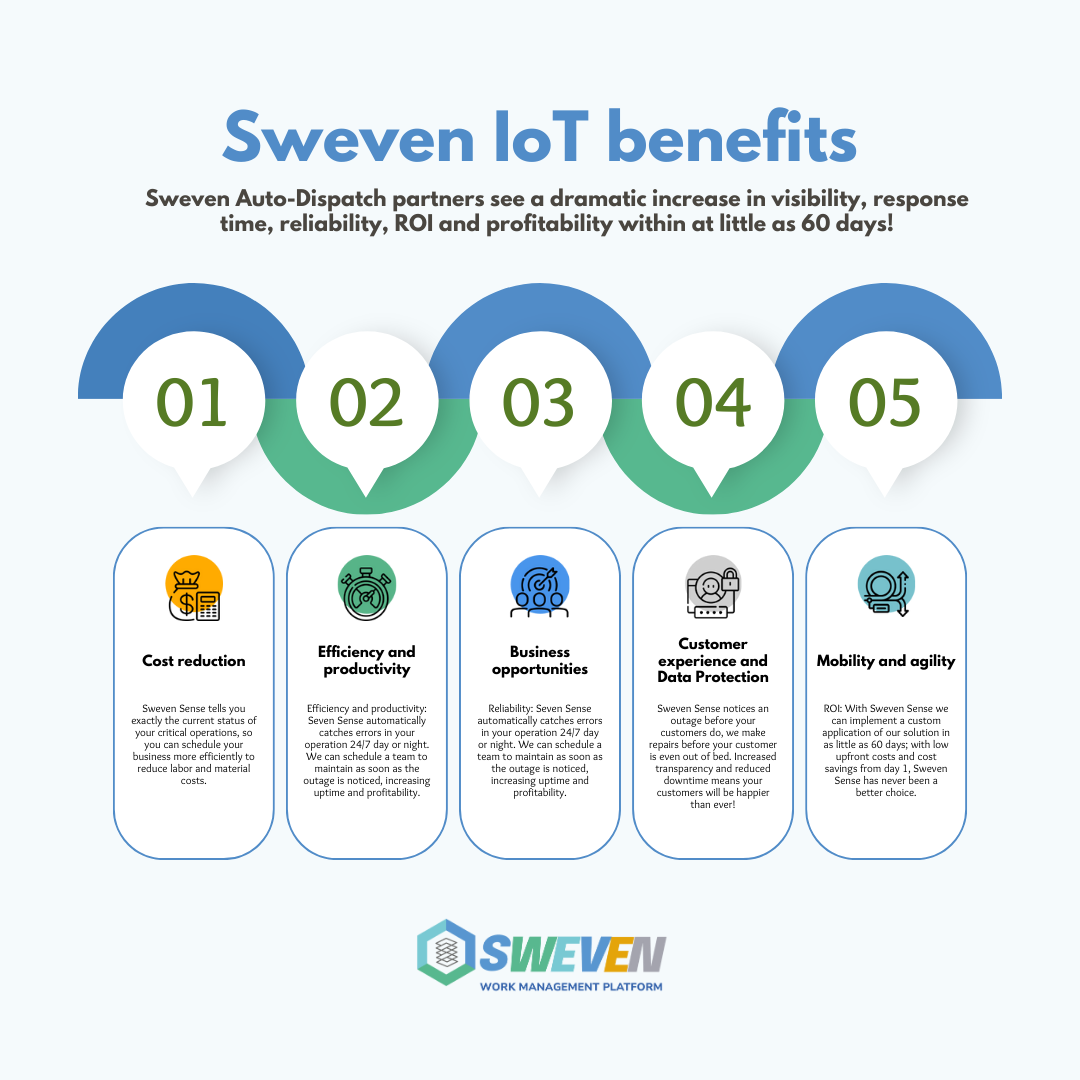

– Performance Metrics: Centralized platforms provide reporting and analytics capabilities that allow teams to track key performance metrics, such as mean time to repair (MTTR), mean time between failures (MTBF), and maintenance costs.

– Trend Analysis: By analyzing historical data and trends, teams can identify patterns, anticipate issues, and implement preventive measures to avoid future breakdowns.

6. Mobile Accessibility

– Mobile Apps: Many centralized communication platforms offer mobile applications that enable maintenance teams to access the platform and collaborate on-the-go, increasing flexibility and responsiveness.

Implementing Centralized Communication Platforms

To successfully implement centralized communication platforms for maintenance teams, organizations should follow a structured approach:

1. Needs Assessment and Planning

– Identify Requirements: Assess the specific communication and collaboration needs of maintenance teams, considering factors such as team size, geographic dispersion, and types of maintenance activities.

– Define Objectives: Clearly define the objectives and goals of implementing a centralized communication platform, such as improving communication, streamlining task management, and reducing downtime.

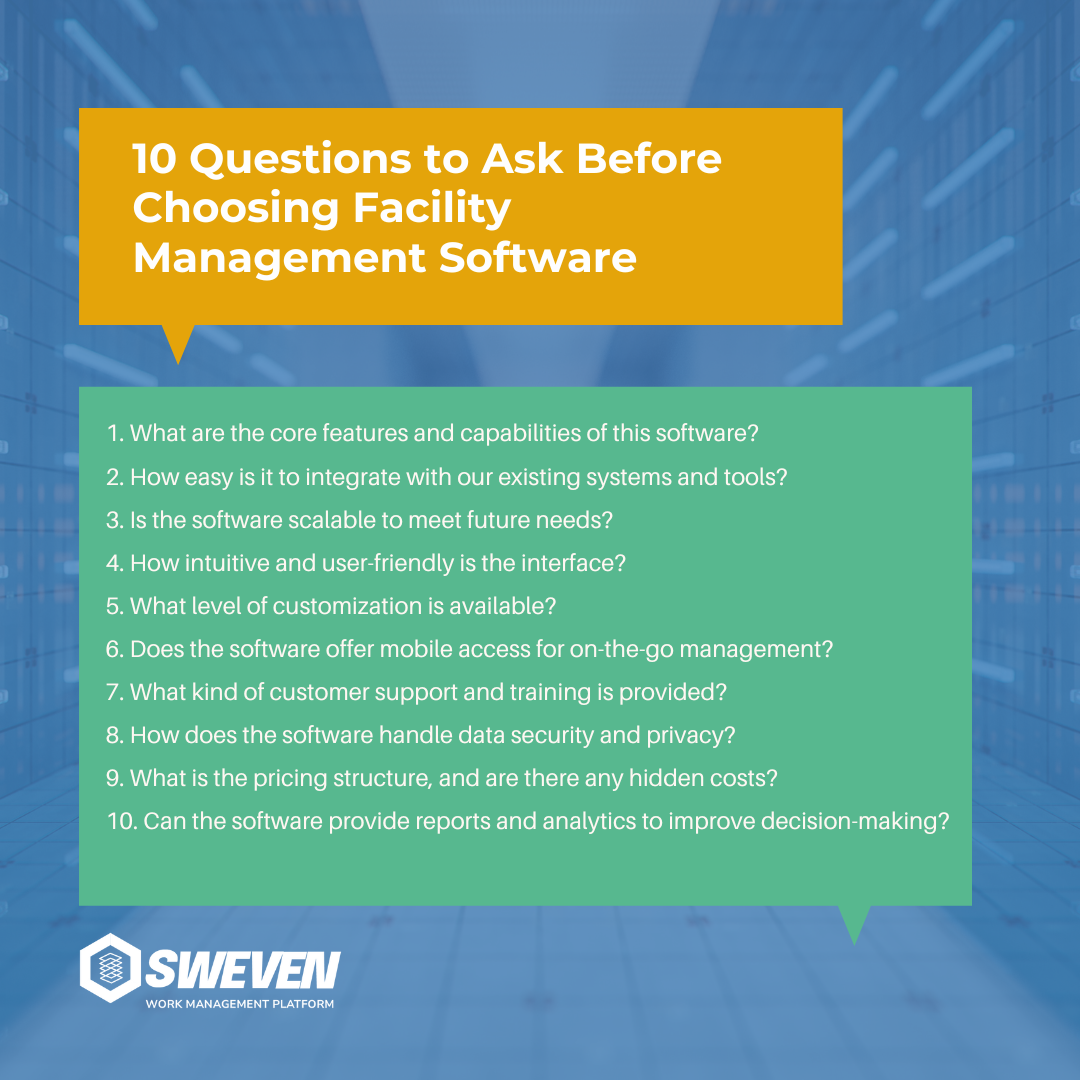

2. Vendor Evaluation and Selection

– Research and Evaluate: Research different centralized communication platforms available in the market and evaluate them based on features, usability, scalability, and cost.

– Trial Period: Consider conducting a trial period or pilot project with selected platforms to assess their suitability and gather feedback from maintenance teams.

3. Training and Adoption

– User Training: Provide comprehensive training to maintenance teams on how to use the centralized communication platform effectively, including features such as task management, document sharing, and reporting.

– Change Management: Implement change management strategies to address any resistance to change and promote adoption of the new platform, emphasizing the benefits and advantages it offers.

4. Integration with Existing Systems

– System Integration: Ensure seamless integration of the centralized communication platform with existing systems and tools used by maintenance teams, such as asset management systems, work order management systems, and Enterprise Resource Planning (ERP) systems.

5. Continuous Improvement

– Feedback Mechanisms: Establish feedback mechanisms to gather input and suggestions from maintenance teams on the usability, functionality, and effectiveness of the centralized communication platform.

– Iterative Improvements: Use feedback received to make iterative improvements to the platform, addressing pain points and enhancing features to better meet the needs of maintenance teams.

Conclusion

The lack of coordination between maintenance teams can hinder organizational efficiency, increase downtime, and impact overall productivity. However, by implementing centralized communication platforms, organizations can facilitate collaboration, streamline communication, and improve coordination among maintenance teams. With features such as real-time communication, task management, document sharing, calendar integration, and mobile accessibility, centralized platforms empower maintenance teams to work more efficiently, resolve issues promptly, and ensure optimal asset performance.

Call to Action

Are you ready to enhance collaboration and coordination among your maintenance teams? Contact us today to learn more about our centralized communication platform solutions. Let us help you streamline maintenance processes, reduce downtime, and improve productivity through effective communication and collaboration tools.