Maintenance aggregators play a critical role in ensuring that physical products remain in top working condition. They coordinate maintenance services, repair parts, and equipment from various vendors to meet the needs of their clients. However, managing inventory levels and forecasting demand can be a daunting task, especially when dealing with multiple vendors. In this blog post, we’ll explore the unique challenges maintenance aggregators face and how implementing an Integrated Inventory Management System (IMS) can provide a comprehensive solution to these complexities.

The Complexities of Inventory Management for Maintenance Aggregators:

Maintenance aggregators encounter a set of distinct challenges when it comes to inventory management:

- Diverse Inventory: They must maintain a diverse range of spare parts, equipment, and tools, each with its own unique demand patterns and shelf life considerations.

- Multiple Vendors: Dealing with numerous vendors means navigating varying lead times, pricing structures, and supply chain complexities.

- Critical Timing: Timeliness is crucial in maintenance operations. Delays in procuring necessary items can lead to costly downtime for clients.

- Unpredictable Demand: Predicting when and where maintenance will be required can be unpredictable, making demand forecasting a constant challenge.

- Cost Constraints: Balancing the need for readily available spare parts with cost constraints can be tricky. Overstocking can tie up capital, while understocking can result in delays.

The Integrated Inventory Management System (IMS) Solution:

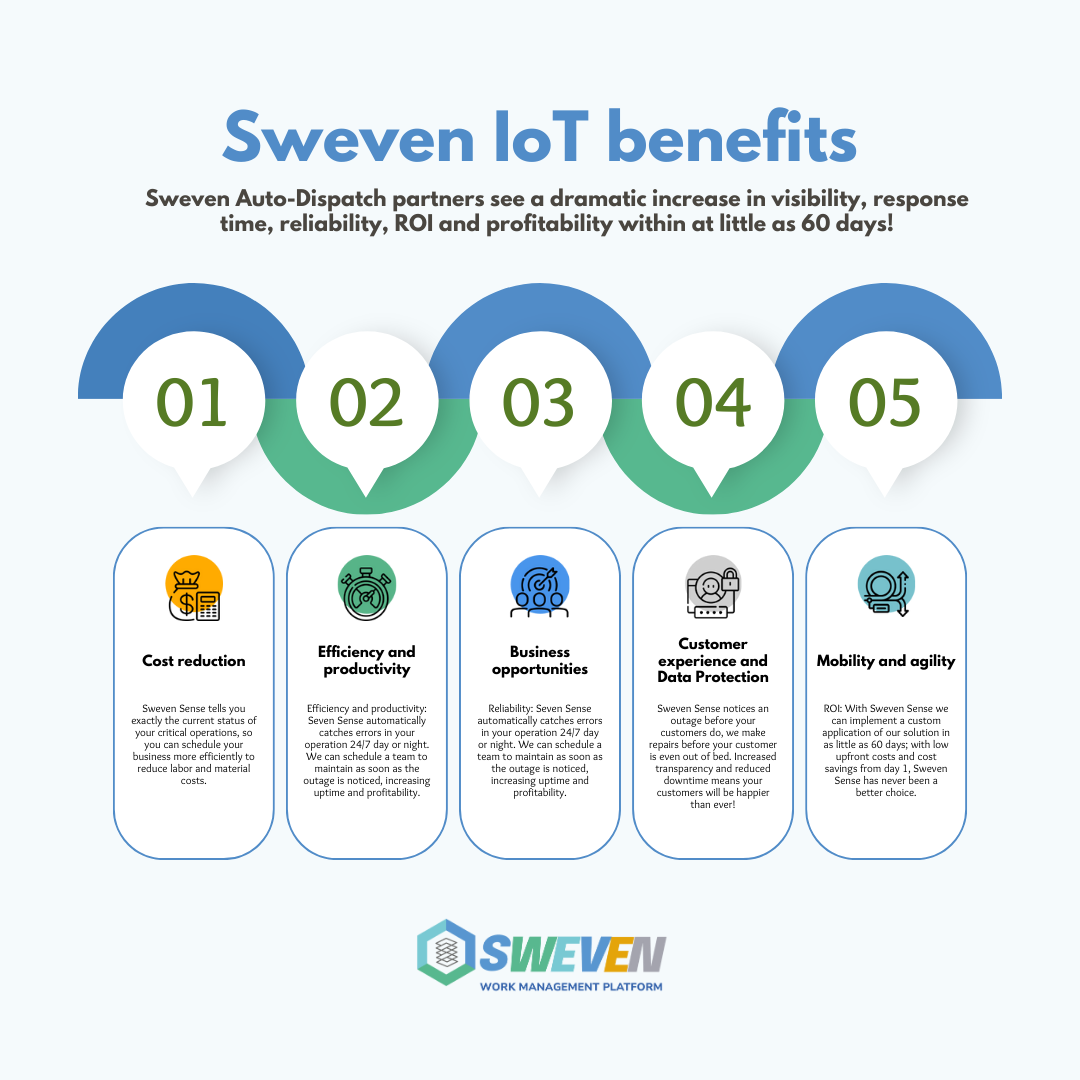

To overcome these challenges, maintenance aggregators can turn to an Integrated Inventory Management System (IMS) as a comprehensive solution. Here’s how an IMS can revolutionize inventory management and demand forecasting for maintenance aggregators:

- Real-time Visibility: An IMS provides a real-time view of inventory levels across all vendors, ensuring that maintenance aggregators always know what parts are available.

- Demand Forecasting: By leveraging historical data and real-time market trends, an IMS automates demand forecasting. This allows maintenance aggregators to anticipate needs, reducing the risk of stockouts or overstocking.

- Optimized Stock Levels: IMS dynamically adjusts stock levels based on demand forecasts. This helps reduce carrying costs while ensuring the availability of critical items when needed.

- Vendor Collaboration: IMS facilitates communication and collaboration with vendors by sharing inventory data and demand forecasts. This transparency can lead to better relationships and improved supply chain efficiency.

- Cost Efficiency: Preventing overstocking and minimizing stockouts leads to cost savings. It frees up capital for investments in other areas of the business.

- Reduced Downtime: With an optimized inventory, maintenance aggregators can respond promptly to client requests, minimizing downtime and maximizing client satisfaction.

- Streamlined Operations: IMS streamlines inventory-related processes, allowing maintenance aggregators to focus on their core competencies—providing top-notch maintenance services.

For maintenance aggregators managing physical products from multiple vendors, implementing an Integrated Inventory Management System (IMS) is a game-changer. It offers real-time visibility, automated demand forecasting, and optimized stock levels, ensuring that critical spare parts and equipment are readily available when needed. In a field where timing is everything, IMS not only streamlines operations but also enhances cost-efficiency, client satisfaction, and overall competitiveness. It’s the tool maintenance aggregators need to thrive in a complex and demanding industry.